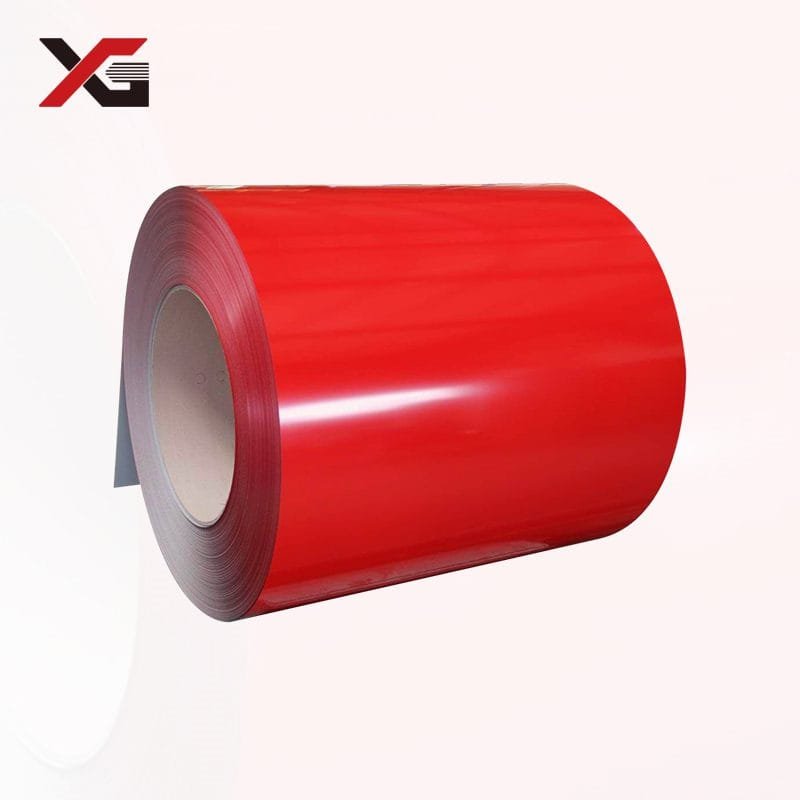

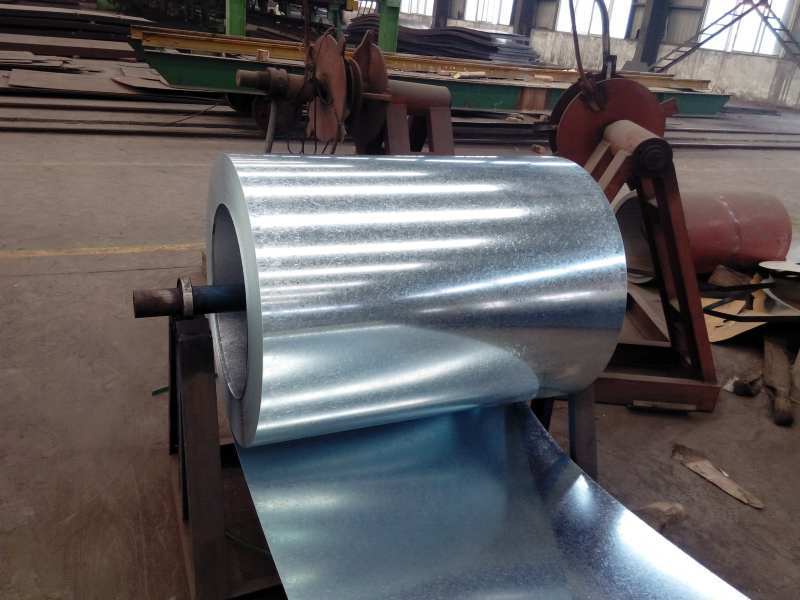

Color-coated coils use hot-dip galvanized sheets, hot-dip galvalume sheets, electro-galvanized sheets, etc. as substrates. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coatings are coated on the surface, and then A product that is baked and solidified. Colored steel coils are named after being coated with organic coatings of various colors, referred to as color-coated coils.

Product Parameters

| Product Name | Pre-painted Galvanized Steel Coil |

| Type | Steel Coil |

| Thickness | 0.12~2.0 mm |

| Width | 600 mm~1500 mm |

| Zn Coating | 0.13-0.8 mm is 30-150 g/㎡; 0.8-1.5 mm is 30-180 g/㎡; 1.5-6.0 mm is 30-275 g/㎡ |

| Coil Weight | 3-6mt |

| Colors | RAL Colors or as customer requirements |

| Surface treatment | Top paint: FVDF, HDP, SMP, PE, PU |

| Prime paint: polyurethane, epoxy, PE | |

| Back paint: epoxy, modified polyester | |

| Standard | ASTM, JIS, EN |

| Certificate | ISO, CE |

| Delivery times | 8-15 days after the receipt of deposit |

| Package | tied up with steel strips and wrapped with water proof paper |

| Loading port | Qingdao, China |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner, outer shell of water machine etc. |

Product Specifications

| Type | Thickness(mm) | Width(mm) | |||

| 1219 | 1500 | 1800 | 2000 | ||

| Cold Rolled | 0.3 | √ | √ | √ | √ |

| 0.4 | √ | √ | √ | √ | |

| 0.5 | √ | √ | √ | √ | |

| 0.6 | √ | √ | √ | √ | |

| 0.7 | √ | √ | √ | √ | |

| 0.8 | √ | √ | √ | √ | |

| 0.9 | √ | √ | √ | √ | |

| 1.0 | √ | √ | √ | √ | |

| 1.2 | √ | √ | √ | √ | |

| 1.5 | √ | √ | √ | √ | |

| 1.8 | √ | √ | √ | √ | |

| 2.0 | √ | √ | √ | √ | |

| 2.5 | √ | √ | √ | √ | |

| 3.0 | √ | √ | √ | √ | |

| 4.0 | √ | √ | √ | √ | |

| 5.0 | √ | √ | √ | √ | |

| 6.0 | √ | √ | √ | √ | |

| Hot Rolled | 4.0 | √ | √ | √ | √ |

| 5.0 | √ | √ | √ | √ | |

| 6.0 | √ | √ | √ | √ | |

| 8.0 | √ | √ | √ | √ | |

| 10.0 | √ | √ | √ | √ | |

| 12.0 | √ | √ | √ | √ | |

| 14.0 | √ | √ | √ | √ | |

| 16.0 | √ | √ | √ | √ | |

| Product Details | Product Production | Product Warehouse |

|  |  |

|  |  |

Applications

PPGI Purpose:

1. Construction field: Color coated steel coils are widely used in fields such as building roofs, wall panels, doors and windows, roof trusses, partitions, and ceilings. Color coated steel coils not only have aesthetic properties, but also have good waterproof, fireproof, and thermal insulation properties, making them an excellent building material.

2. Home appliance field: Color coated steel coils are widely used in making home appliance shells, such as refrigerators, air conditioners, washing machines, microwaves, and electric ovens. Color coated steel coils have characteristics such as wear resistance, corrosion resistance, easy cleaning, and aesthetics, which can meet the appearance and performance requirements of the home appliance industry.

3. Transportation field: Color coated steel coils can be used to make components such as body shells, roof, chassis, and frame. Color coated steel coils have the characteristics of lightweight, high strength, corrosion resistance, wear resistance, and aesthetics, which can improve the safety and aesthetics of transportation vehicles.

4. Furniture field: Color coated steel coils can be used to make furniture such as office furniture, kitchen furniture, bookshelves, and wardrobes. Color coated steel coils have the characteristics of aesthetics, wear resistance, easy cleaning, and corrosion resistance, which can meet the requirements of the furniture industry for material appearance and performance.

5. Electronic equipment field: Color coated steel coils can be used to make electronic equipment casings such as television casings, audio casings, and computer casings. Color coated steel coils have the characteristics of aesthetics, wear resistance, corrosion resistance, and electromagnetic interference resistance, which can improve the safety and aesthetics of electronic equipment.

Project Cases

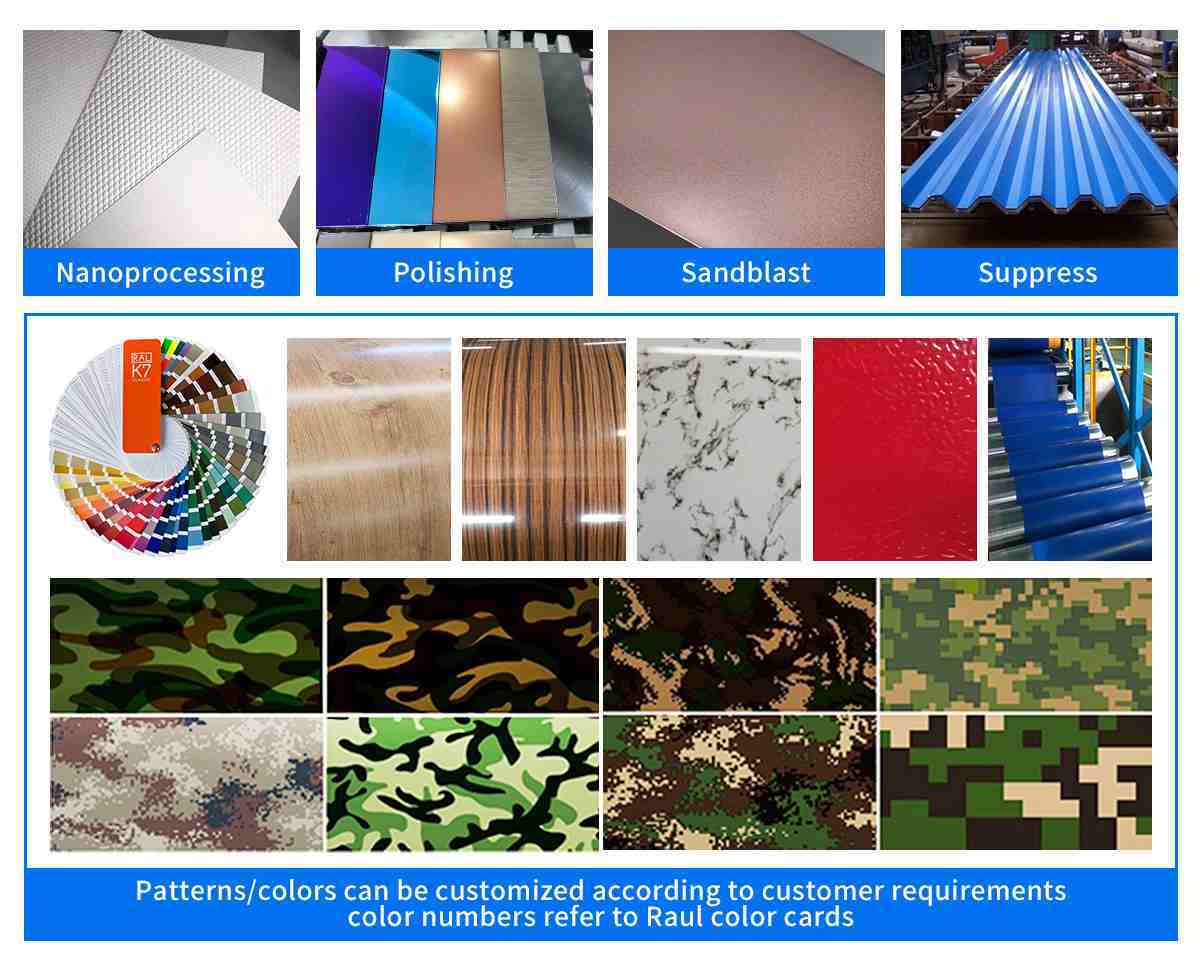

Additional Processing Technology

PPGI can customize patterns/colors according to customer requirements, with color codes referring to the Raul color card

Product Packaging

Product Transportation